Revolutionize the Power of Digital Transformation in Manufacturing

Harnessing the Power of Digital Transformation to Revolutionize Manufacturing

In the competitive landscape of the manufacturing industry in the USA, digital transformation in manufacturing is crucial for unlocking significant operational improvements. McKinsey reports that digital transformation in manufacturing can increase throughput by 10% to 30%, enhance the cost of quality by 10% to 20%, and reduce machine downtime by up to 50%. Despite these transformative benefits, a PwC study reveals that only one-third of manufacturers have advanced beyond the planning phase, missing out on substantial growth opportunities.

IDC

Everest Group

Gartner

At qBotica, we specialize in guiding manufacturing businesses through this critical transformation. As a leading provider of Intelligent ‘Automation as a Service,’ we build comprehensive automation ecosystems tailored to the unique needs of the US manufacturing sector. Our status as a UIPath Platinum Partner underscores our expertise and commitment to delivering exceptional RPA solutions. By partnering with us, you’ll leverage the best-in-class automation technologies and start ‘Thinking inside the Bots’ to drive efficiency and innovation across your operations.

We are more than just a service provider—we are your dedicated partner in achieving digital excellence. Our deep expertise as a certified UIPath Platinum Partner ensures that you receive the highest level of RPA knowledge and technical support. We offer tailored hyperautomation solutions that streamline your manufacturing processes, enhance productivity, and reduce costs. Whether you are embarking on your digital transformation journey in manufacturing or looking to optimize existing systems, qBotica is here to help you realize your full potential.

How Robotic Process Automation Can Simplify the Transition to Digital Transformation in Manufacturing

- Increased Operational Efficiency: Digital manufacturing integrates advanced technologies like IoT, AI, and data analytics to streamline operations. This results in optimized production processes, faster time-to-market, and reduced operational costs.

- Enhanced Data Utilization: By adopting digital manufacturing, companies can leverage real-time data to make informed decisions, predict maintenance needs, and improve overall production quality.

- Cost Reduction: Automation and digital tools help reduce manual intervention, minimize errors, and lower labor costs, contributing to significant savings in production expenses.

- Flexibility and Adaptability: Digital manufacturing enables manufacturers to quickly adapt to changing market demands and customer requirements. This flexibility is crucial for staying competitive in a rapidly evolving industry.

- Streamlined Operations: RPA automates repetitive and time-consuming tasks, enabling your team to focus on more strategic activities. This boosts productivity and ensures routine processes are executed with precision and speed.

- Seamless Integration: Our RPA solutions integrate smoothly with your existing systems, ensuring a hassle-free transition to digital manufacturing. This integration maintains data consistency and operational continuity without disrupting your current operations.

- Enhanced Accuracy and Reliability: Automation through RPA reduces human error and increases the reliability of your manufacturing processes. This leads to improved product quality and consistency, enhancing overall operational performance.

- Scalability: RPA solutions are designed to be scalable, allowing you to expand automation capabilities as your business grows. This flexibility supports evolving manufacturing needs and helps manage increased production volumes effectively.

Current State of Digital Transformation in Manufacturing Industry

Widespread Adoption of Advanced Technologies

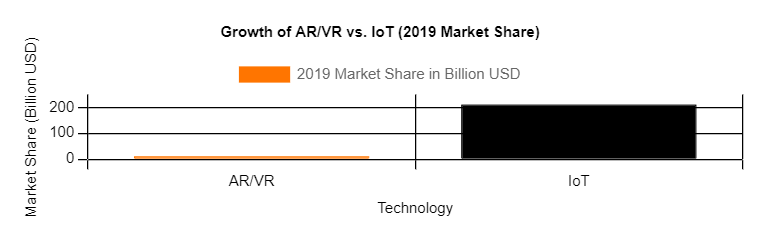

- Internet of Things (IoT): IoT devices are used to monitor and manage equipment and production processes in real-time provides valuable data that helps in predictive maintenance and improves operational efficiency.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms analyze vast amounts of data to optimize production processes, improve quality control, and enable predictive maintenance.

- Robotic Process Automation (RPA): RPA is streamlining repetitive and manual tasks, leading to increased efficiency and reduced errors in manufacturing processes.

- Additive Manufacturing (3D Printing): 3D printing is revolutionizing prototyping and production by enabling rapid, cost-effective creation of complex parts and products.

Emphasis on Data-Driven Decision Making

- Improved Decision Making: Data-driven insights lead to better decision-making, helping manufacturers optimize production schedules, manage inventory, and respond to market changes more effectively.

- Enhanced Quality Control: Advanced analytics identify trends and potential issues early, enabling proactive measures to maintain high product quality and minimize defects.

Integration of Smart Manufacturing Systems

- Cyber-Physical Systems (CPS): CPS combine physical machinery with digital technologies to create interconnected systems that enhance automation and control.

- Digital Twins: Digital twins are virtual replicas of physical assets that allow manufacturers to simulate, predict, and optimize performance in real-time.

- Cloud Computing: Cloud-based platforms provide scalable and flexible solutions for data storage, analysis, and collaboration, supporting digital transformation efforts across the supply chain.

Challenges and Barriers to Adoption

- High Implementation Costs: The initial investment required for digital technologies and infrastructure can be significant, posing a barrier for smaller manufacturers.

- Data Security Concerns: As manufacturing operations become more digital, the risk of cyber threats and data breaches increases, necessitating robust security measures.

- Skill Gaps: There is a growing need for skilled professionals who can manage and utilize advanced digital technologies. Addressing these skill gaps is crucial for successful digital transformation.

- Change Management: Transitioning to digital processes requires a shift in organizational culture and mindset. Manufacturers must manage this change effectively to ensure a smooth adoption process.

Future Directions

- Increased Use of Artificial Intelligence: AI will play a larger role in optimizing production processes, enhancing predictive maintenance, and enabling autonomous operations.

- Greater Emphasis on Sustainability: Digital technologies will support sustainable manufacturing practices by improving resource efficiency and reducing waste.

- Enhanced Collaboration: Digital tools will foster greater collaboration across the supply chain, leading to more integrated and responsive manufacturing ecosystems.

Focus on Customer-Centric Innovation

- Personalization: Leveraging digital tools to offer customized products and solutions that meet specific customer needs, enhancing overall satisfaction and loyalty.

- Enhanced Customer Interaction: Utilizing digital platforms to improve customer engagement and feedback loops, ensuring that products and services align with market demands.

- Agile Development: Implementing digital technologies to accelerate product development cycles and respond more quickly to changing customer preferences and market trends

More To Explore In Manufacturing

Transform Your Business with GenAI: Document Processing at Scale

Generative AI (GenAI) trained for document processing is transforming business operations at scale. This advanced technology enables organizations to handle vast volumes of documents with unparalleled accuracy and efficiency. By leveraging GenAI, businesses can automate tedious tasks, extract valuable insights from unstructured data, and streamline workflows. UiPath’s Intelligent Document Processing (IDP) solutions play a crucial role in this evolution. As a leader in robotic process automation (RPA) and AI, UiPath offers cutting-edge tools designed to enhance productivity and maintain a competitive edge in today’s fast-paced digital landscape. Their IDP solutions are specifically tailored to manage complex document-based processes, ensuring that businesses stay ahead of the curve. Key Benefits: Increased Efficiency: Automate repetitive tasks, reducing manual intervention. Enhanced Accuracy: Minimize errors in data extraction and classification. Scalability: Handle large volumes of documents effortlessly. Adopting GenAI-driven document processing solutions like those offered by UiPath not only optimizes operations but also unlocks new

Generative AI Glossary: Understanding the Latest Terminology

Generative AI is an exciting branch of artificial intelligence that focuses on creating new content from existing data. It can produce text, images, videos, and other forms of media by analyzing patterns in training data, imitating human creativity without having consciousness or emotions. Understanding the terminology associated with this technology is crucial. The ultimate AI glossary: Artificial intelligence definitions to know serves as a valuable resource for anyone looking to delve deeper into the world of AI. Knowing these terms helps in grasping how these technologies work and their potential applications. In this article, you will: Gain a comprehensive understanding of key terms in the generative AI landscape. Explore different types of AI and their applications across various sectors such as supply chain and logistics or industrial manufacturing. Learn about the core technologies driving generative AI and their practical uses, including the concept of an Automation Center of Excellence which

How Automation Centers of Excellence Are Transforming Businesses

What Is an Automation Centers of Excellence? An Automation Centers of Excellence (CoE) is an internal team or organizational unit dedicated to streamlining automation initiatives within a business. It serves as a centralized resource for establishing standards, processes, and governance models, ensuring effective use of automation technologies across various departments. The CoE plays a crucial role in driving successful automation projects by providing leadership, expertise, and support. Key benefits of establishing a CoE Key benefits that businesses can achieve through the establishment of a CoE include: Increased Efficiency: Automation reduces manual tasks, enabling employees to focus on higher-value activities. For instance, Intelligent Automation Benefits on Finance and Accounting are significant as it allows finance professionals to concentrate on strategic decision-making rather than mundane data entry. Cost Savings: Automated processes minimize human error and reduce operational costs. Accelerated Digital Transformation: A CoE facilitates the integration of advanced technologies like Robotic Process

Embrace the Future with Digital Transformation in Manufacturing

Unlock Your Potential with Cutting-Edge Digital Solutions

Why Digital Transformation Matters

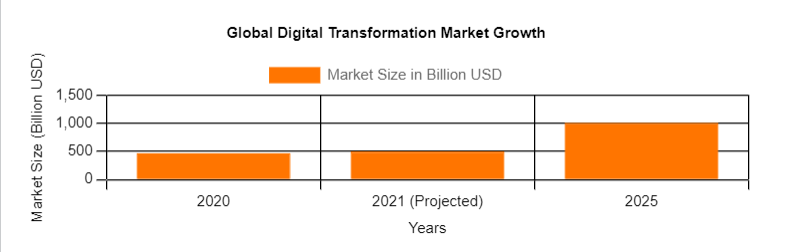

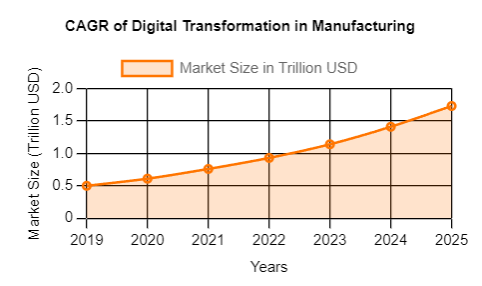

Market Growth and Adoption Trends

Global Digital Transformation Market Growth

- 2020: $469.8 billion

- 2025: $1,009.8 billion

- CAGR: 16.5%

Sector-Specific Insights: Manufacturing

The Benefits of Digital Transformation in Manufacturing

- Enhanced Efficiency

- Increased Productivity

- Improved Decision-Making

- Competitive Edge

Real-World Examples

- Industrial Digital Transformation

- Digital Manufacturing Solutions

Embracing Digital Transformation in Manufacturing Industry

Unlocking the Future of Manufacturing with Digital Transformation

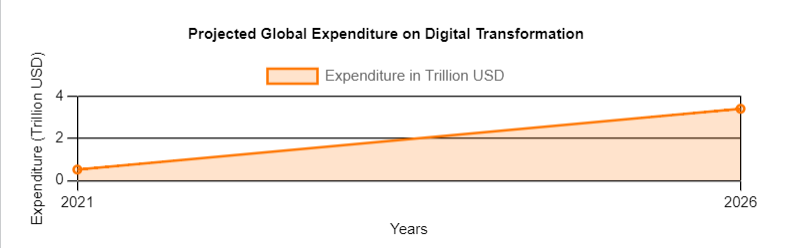

Digital Transformation Market Spending Forecast

- 2022: $1.8 trillion

- 2025: $2.8 trillion

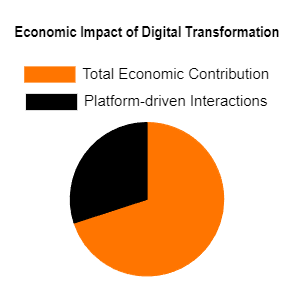

- By 2025: Potential to reach $100 trillion in societal and industrial value

Digital Transformation Stats on Current Business Adoption

- 91% of businesses are engaged in some form of digital initiative.

- 87% of senior business leaders prioritize digitalization.

- 89% of companies have adopted or plan to adopt a digital-first strategy.

The Importance of Digital Strategy in Manufacturing

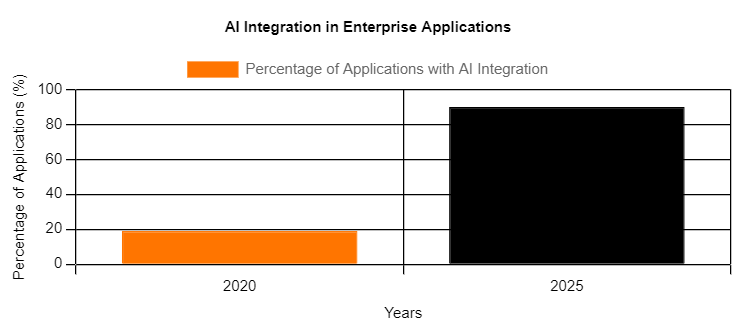

- 60% of data used for AI will be artificially generated by 2024, a significant increase from 1% in 2021.

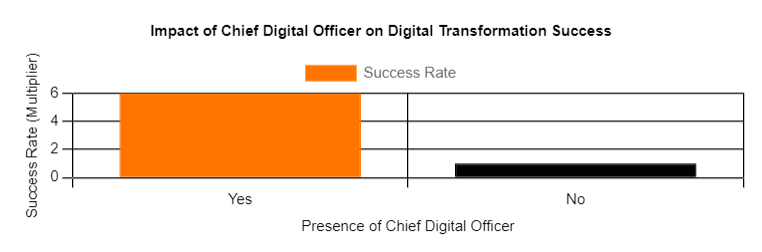

- 28% of digital transformation initiatives are led by CIOs, with 23% increasingly overseen by CEOs.

- By 2025, 75% of business executives will adapt to new markets using digital platforms.

- 60% of mainstream companies will aim to become composable businesses, enhancing their agility in implementing new features.

Cloud Adoption and Emerging Technologies

- Global Cloud Security Market: Expected to grow from $40.7 billion in 2023 to $62.9 billion by 2028.

- AI Spending: Companies spent $58.3 billion on AI in 2021, projected to increase to $309.6 billion by 2026.

- Cloud Storage Market: Expected to be worth more than $390 billion by 2028.

- Industry Cloud Platforms: More than 50% of enterprises will adopt these platforms by 2027 to accelerate operations.

Enhancing Customer Experience Through Digital Transformation

- 54% of transformation efforts focus on modernizing customer touchpoints.

- The customer experience management market is anticipated to grow from $11.56 billion in 2022 to $29.78 billion by 2028.

- 86% of customers would stop engaging with a brand after a single poor experience.

Frequently Asked Questions

- Process Transformation: Improving and automating business processes to increase efficiency and reduce costs.

- Business Model Transformation: Adapting or creating new business models to leverage digital technologies and meet market demands.

- Domain Transformation: Reimagining and innovating within specific domains or industries through digital technologies.

- Cultural Transformation: Shifting organizational culture to embrace digital technologies and foster a more agile, data-driven mindset.

- Smart Manufacturing: Utilizing digital technologies to create interconnected and automated manufacturing systems that enhance efficiency and flexibility.

- Digital Twins: Creating virtual models of physical assets to simulate, analyze, and optimize performance in real-time.

- Data Analytics: Leveraging data collected from various sources to gain insights, improve decision-making, and enhance production processes.